-

How does the aerosol valve assembly machine ensure precise alignment and insertion of valves into aerosol cans?

Sensor Technology: Modern aerosol valve assembly machines employ sophisticated optical and proximity sensors. These sensors are strategically positioned to detect the precise location and orientation ...

Read More >> -

How does the fine mist plastic sprayer automatic assembly machine handle the sealing and alignment of sprayer components?

Alignment Mechanisms: The assembly machine employs sophisticated mechanical guides, fixtures, and robotic arms to ensure precise alignment of sprayer components. These mechanisms are crucial for maint...

Read More >> -

How does the lotion pump automatic assembly machine handle components like springs, valves, and nozzles during assembly?

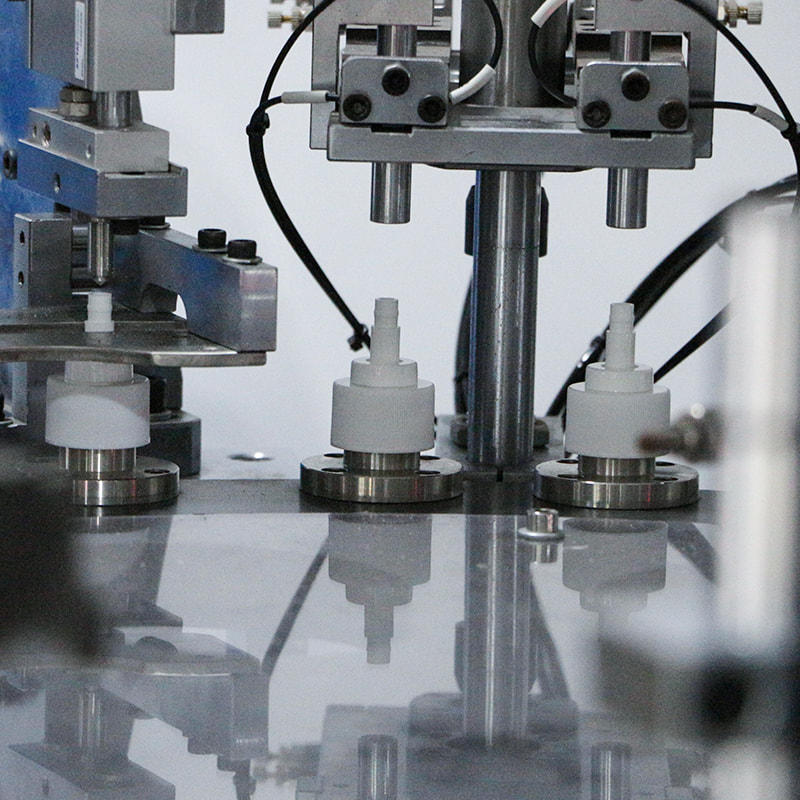

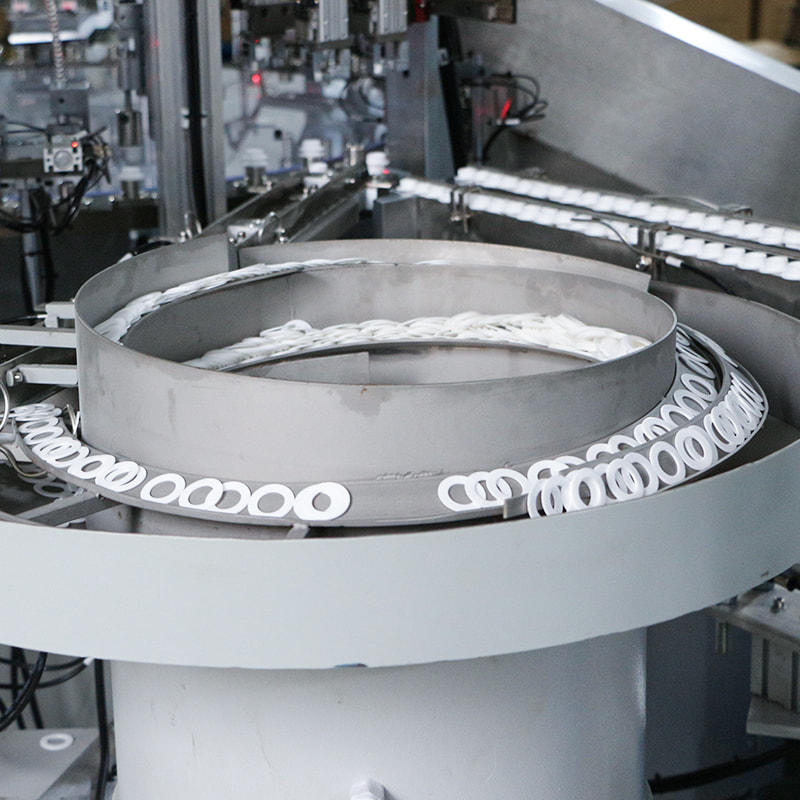

Feeding Mechanism: The assembly machine utilizes sophisticated feeding systems to ensure a continuous supply of components. Vibratory feeders or bowl feeders are commonly employed, equipped with senso...

Read More >> -

What safety features are incorporated into the bag package automatic assembly machine to prevent accidents or product contamination?

Safety features incorporated into a bag package automatic assembly machine typically include: Guarding and Enclosures: Bag package automatic assembly machines are equipped with robust physical barrier...

Read More >>

Product

Lotion Pump Assembly Machine Manufacturers

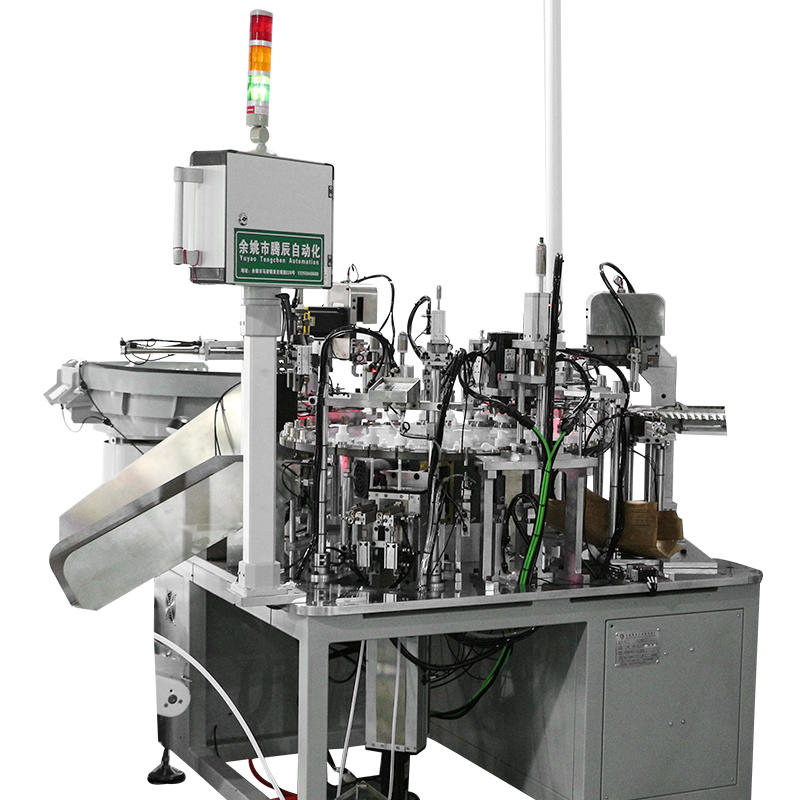

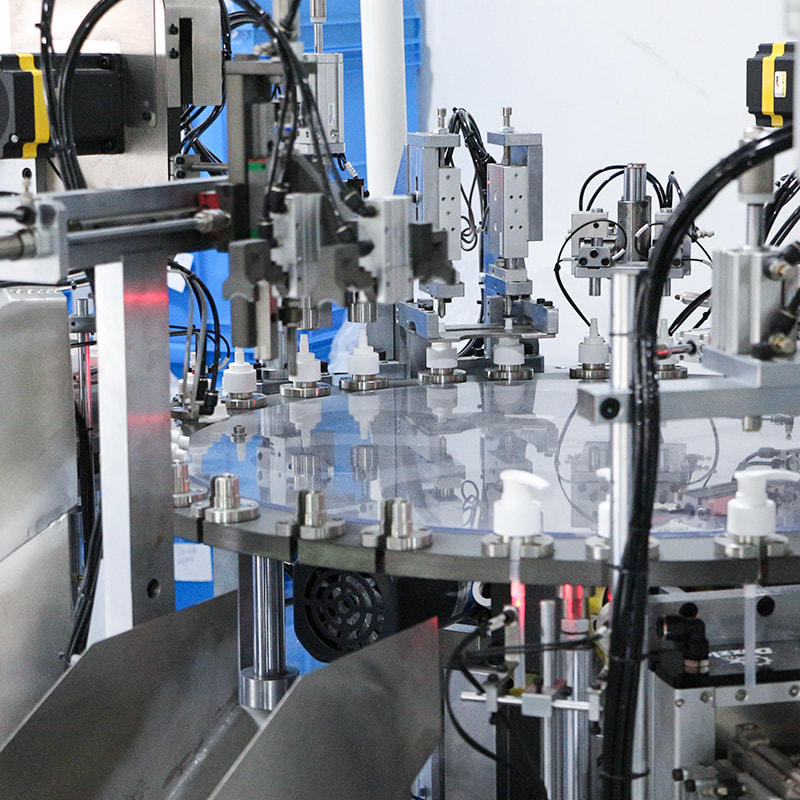

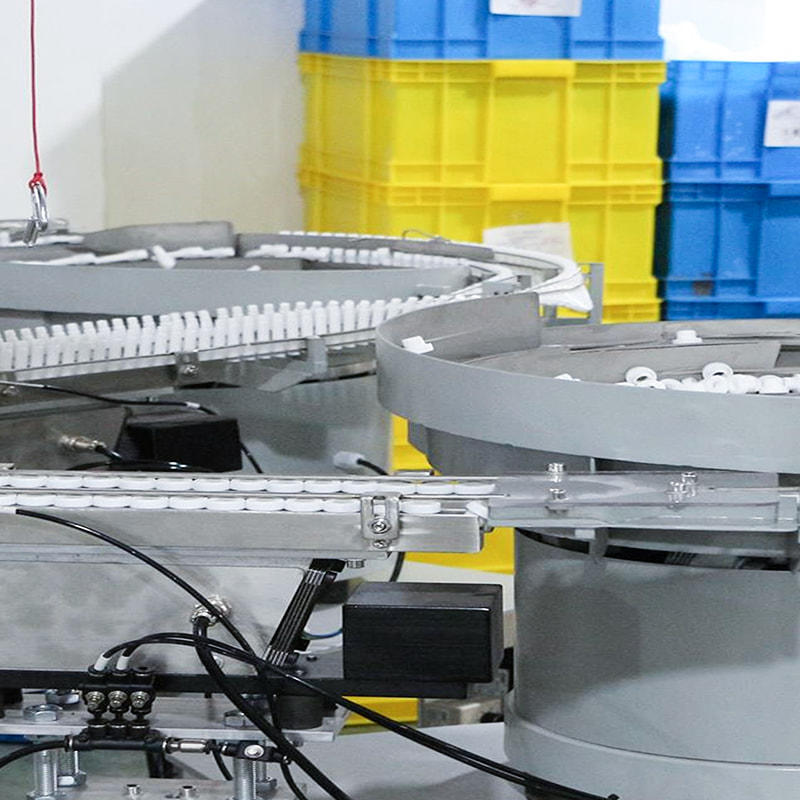

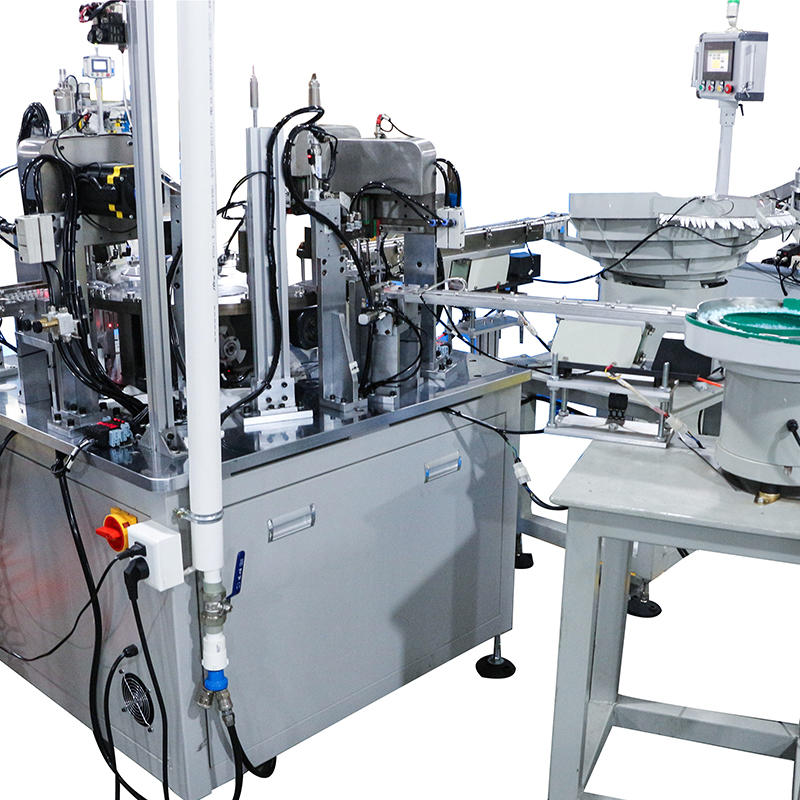

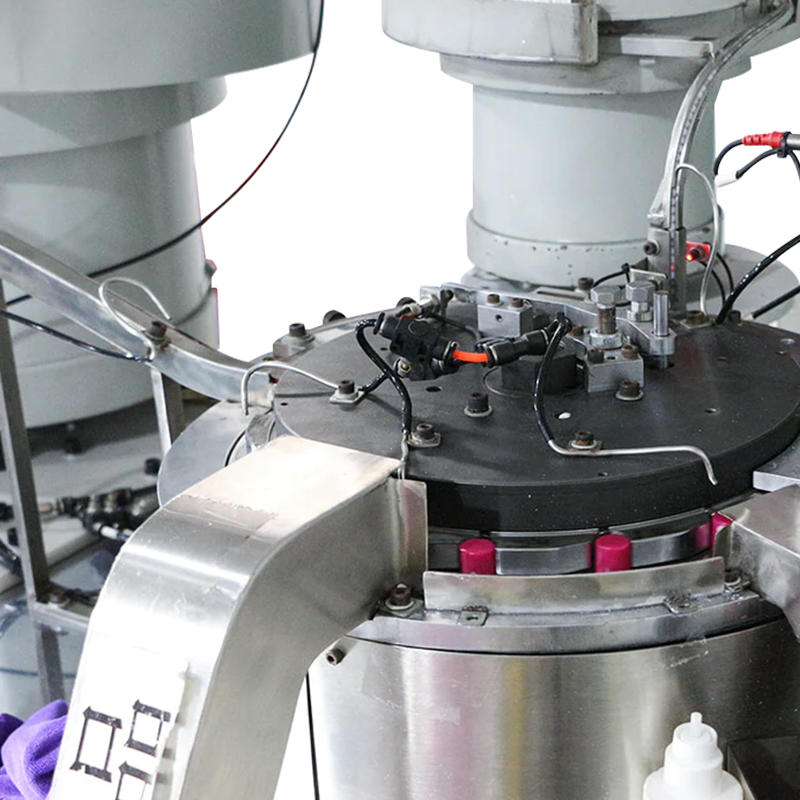

An automatic assembly machine for lotion pump is a machine designed to assemble various components of a lotion pump in an automated manner. These machines are typically used in manufacturing plants where large quantities of lotion pumps need to be produced efficiently.

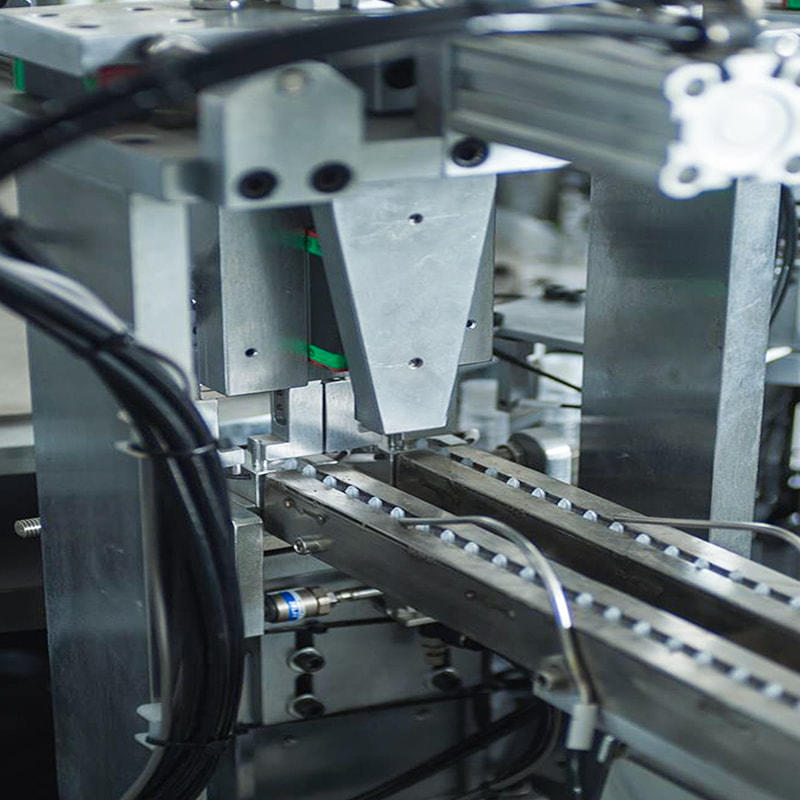

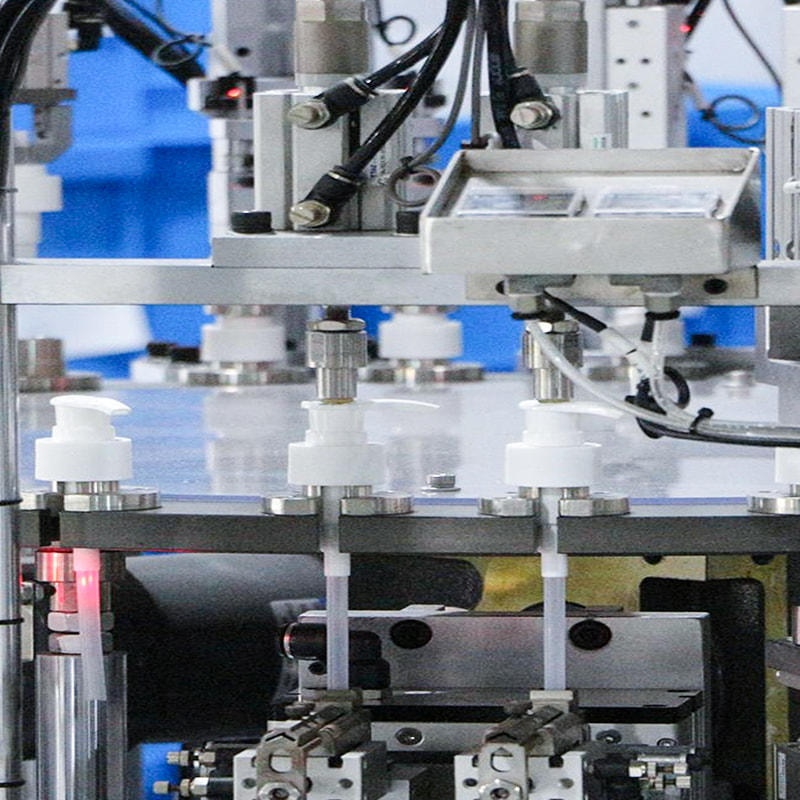

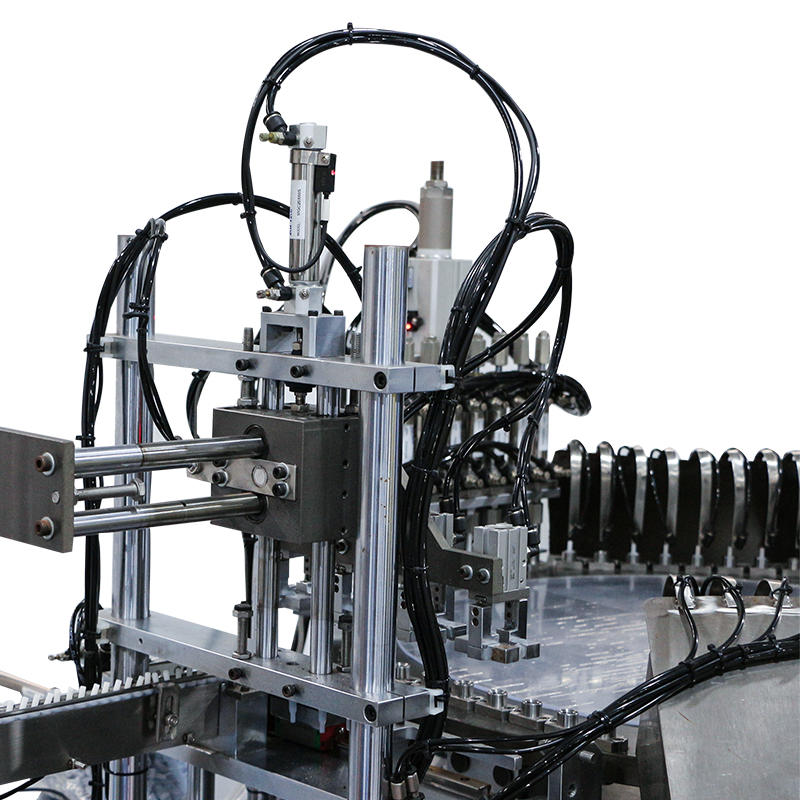

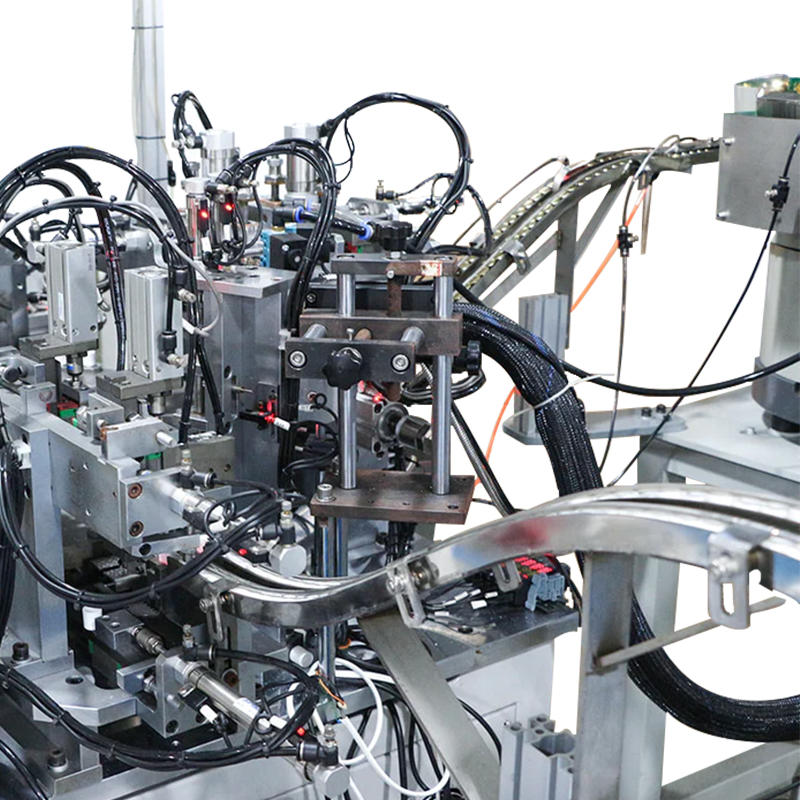

The machine typically consists of a series of stations where different components of the lotion pump are assembled. These stations are typically equipped with robotic arms and other automation equipment that perform specific tasks such as inserting a dip tube or attaching the pump head to the bottle.

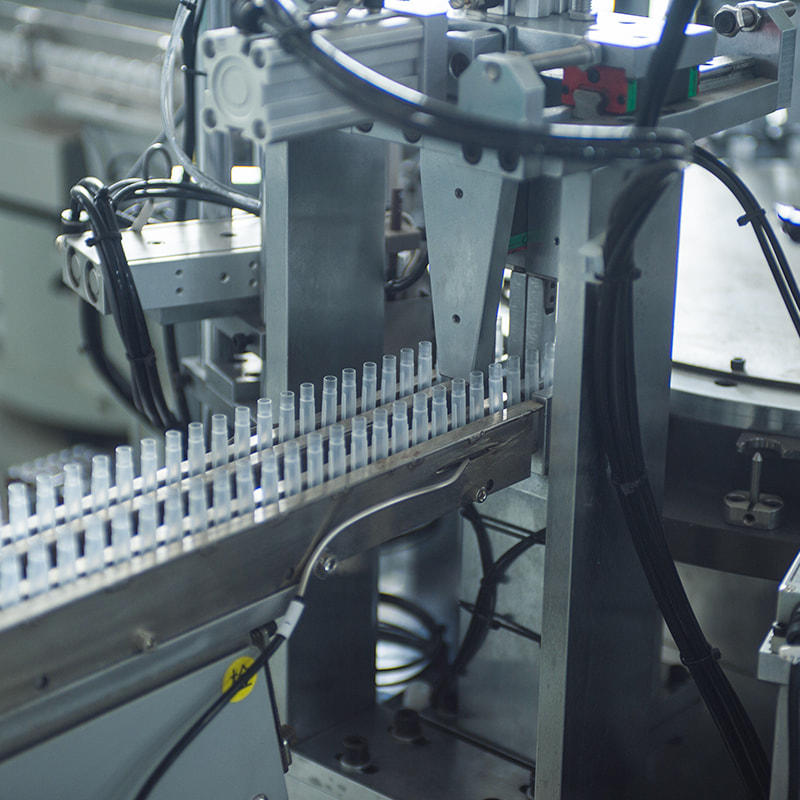

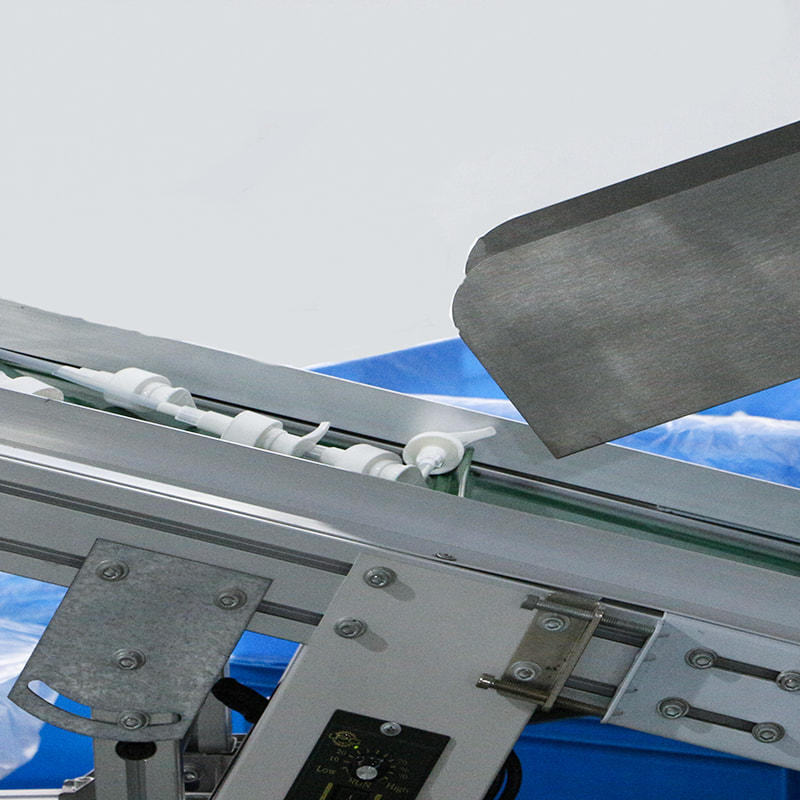

The lotion pump components are usually fed into the machine using a conveyor system or other automated feeding mechanism. As the components move through the machine, the various assembly stations perform their tasks, gradually building up the complete lotion pump.

At the end of the process, the fully assembled lotion pumps are usually inspected for quality and packaged for shipment. These machines can significantly increase the efficiency of lotion pump production, reducing labor costs and improving overall output.

Product Details

| Model:TY-A1 | TY-A1 |

- TY-A1

- TY-A2

- TY-A3

| Model | TY-A1 |

| Name | Lotion pump assembly machine |

| Material | Imported iron / aviation aluminum |

| Application Type | spray pump/trigger pump |

| Voltage | 220v/380v 50Hz |

| Power | ≈1.1kw |

| Production capacity | 80-120pcs/min |

| Working mode | Pneumatic/fully automatic |

| Display method | Human-machine interface HIMI |

| Operators | One person can operate multiple units |

| Minimum order quantity | 1 |

| LOGO customization | Provided |

| Customized outer packaging | Provided |

| Pattern customization | Provided |

| Status | New |

| Weight | 1000kg |

| Video factory inspection | Provided |

| Mechanical test reports | Provided |

| Marketing Type | Hot Product 2022 |

| Core component warranty period | More than 5 years |

| Core Components | SMC/FESTO/CKD cylinder |

| PLC | Delta |

| Relays | Omron |

| Servo Motor | Delta/Nakawa |

| Touch Screen | Siemens |

| Pneumatic Components | Adecco/SMC |

| Wire track | HIWIN/Shengong |

| External Interface | RS232 |

| Sensors | Huayi Feng / Keenes |

| Warranty | More than 5 years |

| Applicable industries | Manufacturing Plant |

| Unit of measurement | Set |

| Payment Method | L/C T/T |

| Logistics Model | Courier / Sea Freight |

| Sea ports | Ningbo |

| Supply capacity | 10 sets per month |

| Packaging method | Wooden package |

| After-sales (put custom properties) | Provided |

| Size | 3800*2700*1700mm |

| Workspace | 3800*2700*1700mm |

| Model | TY-A2 |

| Name | Lotion pump assembly machine |

| Material | Imported iron / aviation aluminum |

| Application Type | spray pump/trigger pump |

| Voltage | 220v/380v 50Hz |

| Power | ≈1.1kw |

| Production capacity | 80-120pcs/min |

| Working mode | Pneumatic/fully automatic |

| Display method | Human-machine interface HIMI |

| Operators | One person can operate multiple units |

| Minimum order quantity | 1 |

| LOGO customization | Provided |

| Customized outer packaging | Provided |

| Pattern customization | Provided |

| Status | New |

| Weight | 1000kg |

| Video factory inspection | Provided |

| Mechanical test reports | Provided |

| Marketing Type | Hot Product 2022 |

| Core component warranty period | More than 5 years |

| Core Components | SMC/FESTO/CKD cylinder |

| PLC | Delta |

| Relays | Omron |

| Servo Motor | Delta/Nakawa |

| Touch Screen | Siemens |

| Pneumatic Components | Adecco/SMC |

| Wire track | HIWIN/Shengong |

| External Interface | RS232 |

| Sensors | Huayi Feng / Keenes |

| Warranty | More than 5 years |

| Applicable industries | Manufacturing Plant |

| Unit of measurement | Set |

| Payment Method | L/C T/T |

| Logistics Model | Courier / Sea Freight |

| Sea ports | Ningbo |

| Supply capacity | 10 sets per month |

| Packaging method | Wooden package |

| After-sales (put custom properties) | Provided |

| Size | 3800*2700*1700mm |

| Workspace | 3800*2700*1700mm |

| Model | TY-A3 |

| Name | Lotion pump assembly machine |

| Material | Imported iron / aviation aluminum |

| Application Type | spray pump/trigger pump |

| Voltage | 220v/380v 50Hz |

| Power | ≈1.1kw |

| Production capacity | 80-120pcs/min |

| Working mode | Pneumatic/fully automatic |

| Display method | Human-machine interface HIMI |

| Operators | One person can operate multiple units |

| Minimum order quantity | 1 |

| LOGO customization | Provided |

| Customized outer packaging | Provided |

| Pattern customization | Provided |

| Status | New |

| Weight | 1000kg |

| Video factory inspection | Provided |

| Mechanical test reports | Provided |

| Marketing Type | Hot Product 2022 |

| Core component warranty period | More than 5 years |

| Core Components | SMC/FESTO/CKD cylinder |

| PLC | Delta |

| Relays | Omron |

| Servo Motor | Delta/Nakawa |

| Touch Screen | Siemens |

| Pneumatic Components | Adecco/SMC |

| Wire track | HIWIN/Shengong |

| External Interface | RS232 |

| Sensors | Huayi Feng / Keenes |

| Warranty | More than 5 years |

| Applicable industries | Manufacturing Plant |

| Unit of measurement | Set |

| Payment Method | L/C T/T |

| Logistics Model | Courier / Sea Freight |

| Sea ports | Ningbo |

| Supply capacity | 10 sets per month |

| Packaging method | Wooden package |

| After-sales (put custom properties) | Provided |

| Size | 3800*2700*1700mm |

| Workspace | 3800*2700*1700mm |

about tengyu

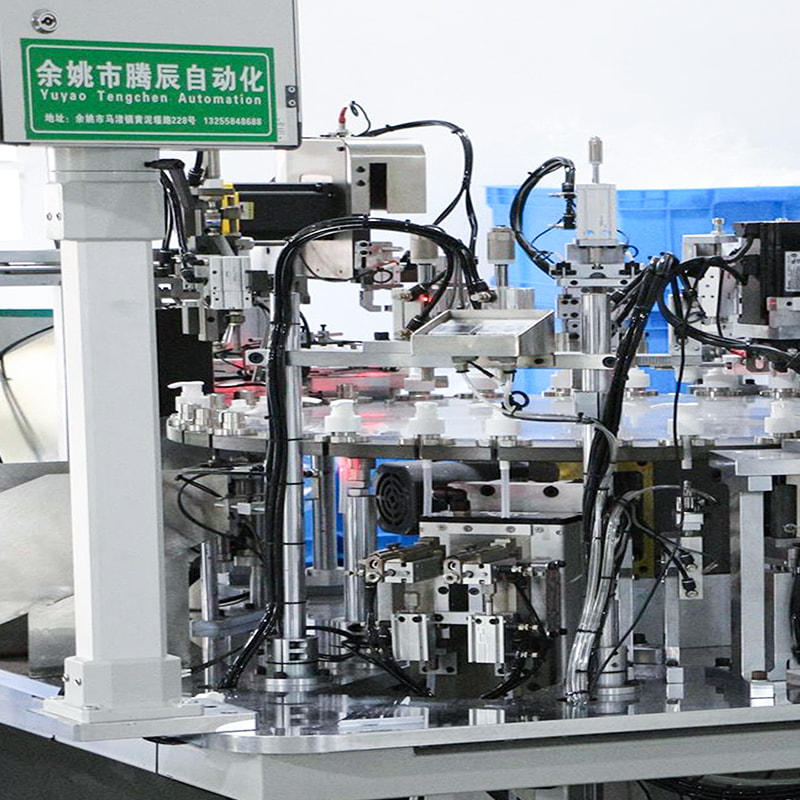

Produce Machines That Satisfy Customers

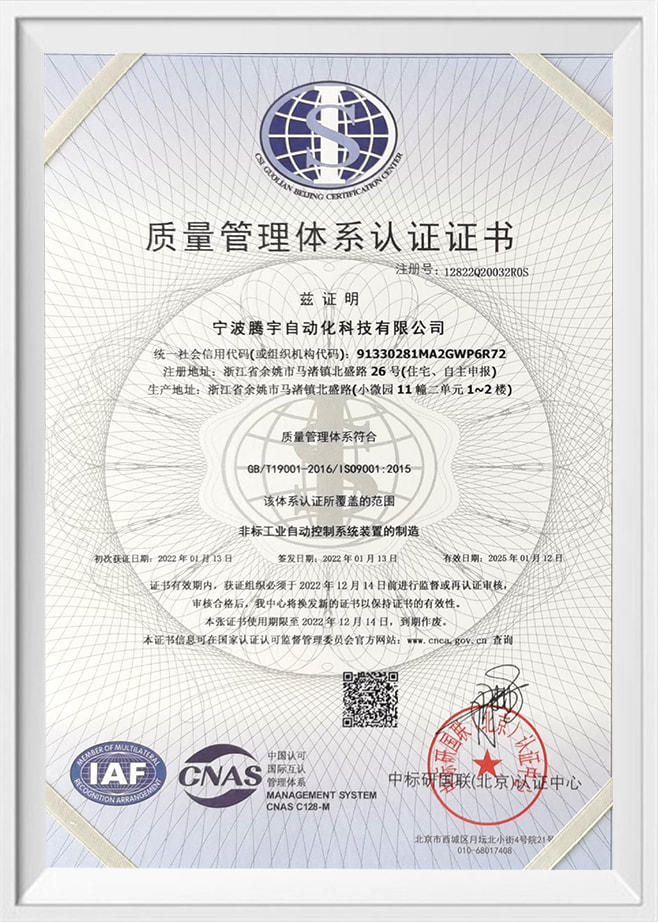

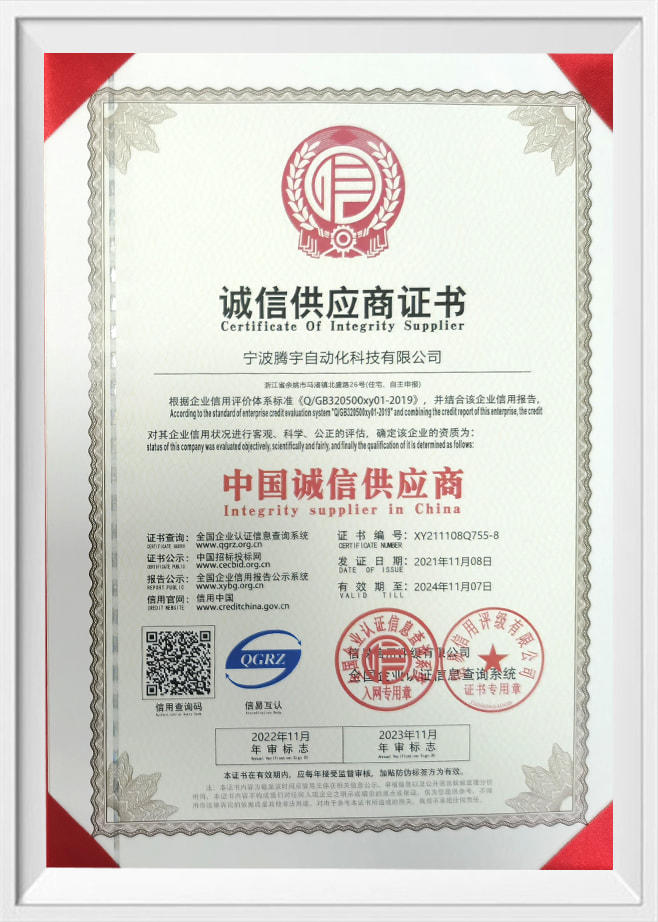

Ningbo Teng Yu Automation Technology Co., Ltd. is located in Mazhu, the thousand-year old town of Yuyao, founded in 2013. As a professional China Lotion Pump Assembly Machine Factory and offer Custom Lotion Pump Assembly Machine service, has accumulated rich experience in the automation equipment industry and has become a benchmark enterprise in the automation equipment industry. At present, the company covers an area of 5,000 square meters and has 50 employees, of whom 40% are senior technicians who have been in the industry for more than 10 years.

Our main products are automatic assembly of plastic products for sterilization, automatic assembly of plastic products for daily cleaning and automatic assembly of plastic products for cosmetic packaging. And we are a professional production and processing enterprise integrating plastic products production, mold design, steel mold manufacturing and automation equipment production.

We are able to meet the specific needs of different customers. With rich experience in design and debugging. The factory has established a perfect pre-sales, in-sales and after-sales service system to meet the needs of all customers with reliable and stable products and efficient and high quality services. We mainly export to more than 20 countries such as Russia, Spain, Italy, Germany, Australia, Algeria, etc.

LATEST & NEWS

We are committed to providing our customers with first-rate products and services that will fulfill your business, small and big.

русский

русский Español

Español عربى

عربى