What are the key features and benefits of the Disc Top Cap Automatic Assembly Machine?

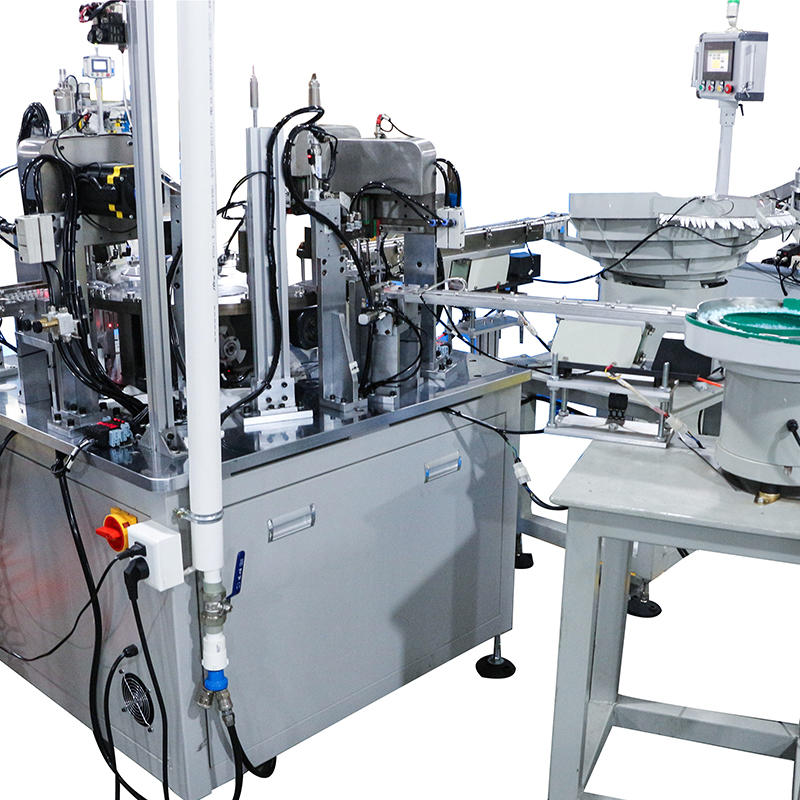

The key features and benefits of the

TengYu Disc Top Cap Automatic Assembly Machine are as follows:

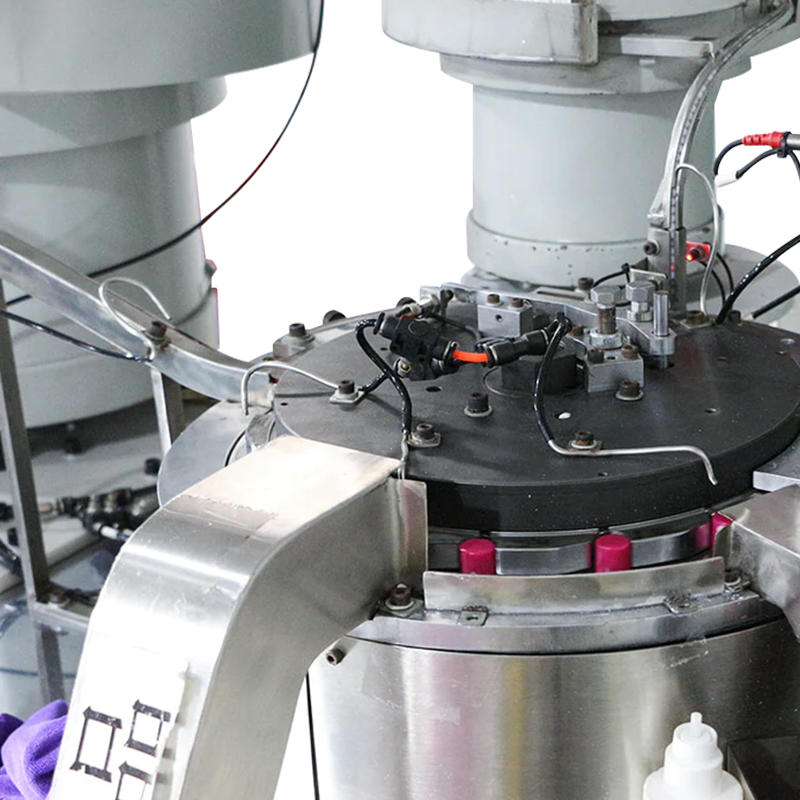

1.High Efficiency: The machine is designed to assemble disc top caps rapidly, increasing production speed and overall efficiency.

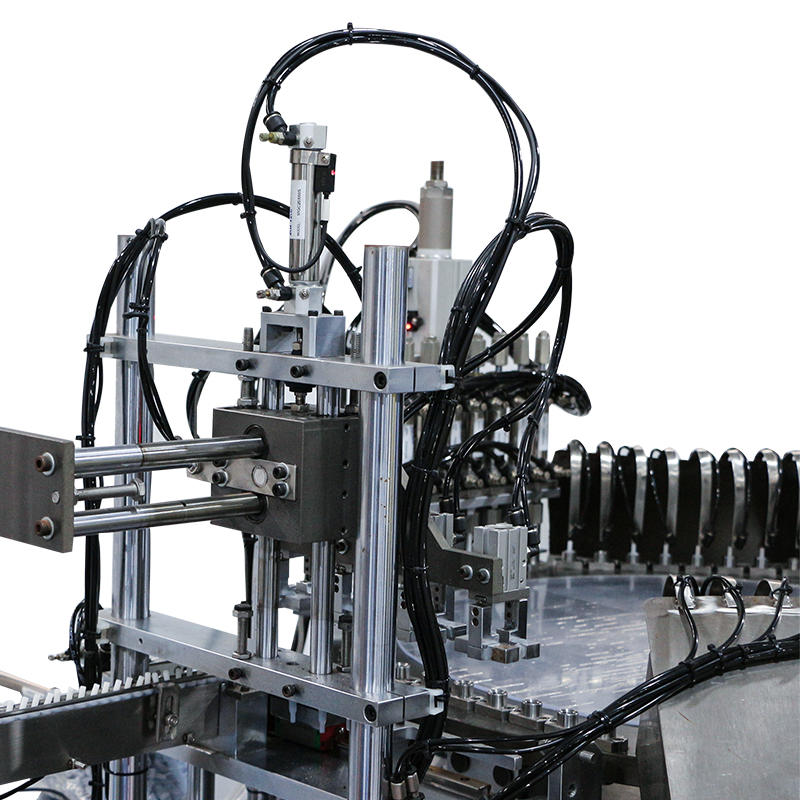

2.Precision Assembly: It ensures precise alignment and secure attachment of the disc top caps, minimizing errors and ensuring consistent quality.

3.Versatility: The machine can accommodate a wide range of disc top cap sizes and designs, making it suitable for various industries and product types.

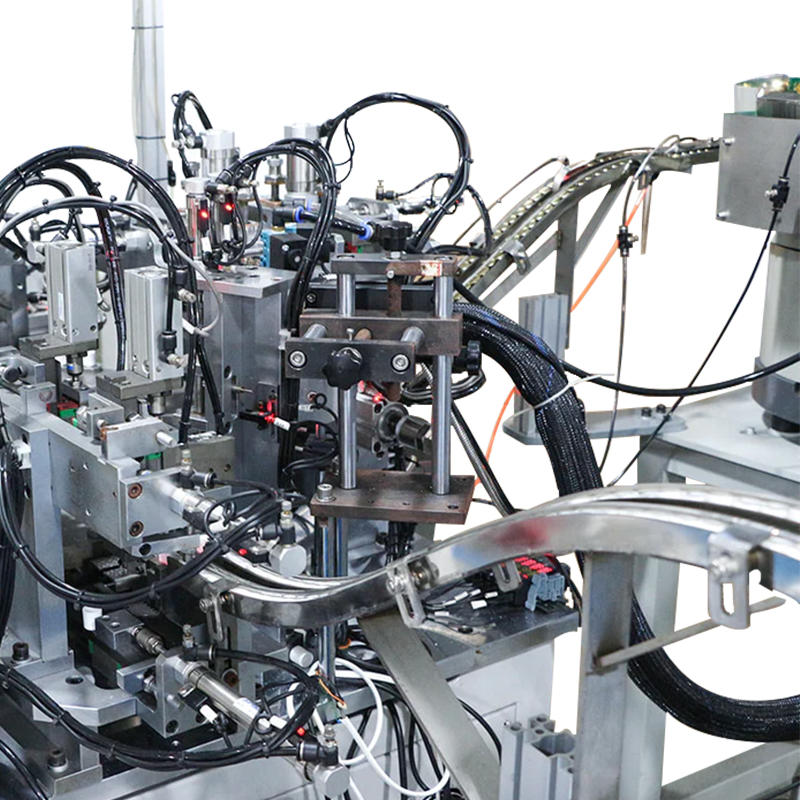

4.Automation: It operates automatically, reducing the need for manual labor and minimizing human error, resulting in improved productivity and cost savings.

5.Easy Setup and Operation: The machine is user-friendly and requires minimal setup and training, enabling quick integration into existing assembly lines.

6.Flexibility: The machine can be easily adjusted to meet changing production requirements, allowing for efficient customization and adaptation to different cap designs.

7.Compact Design: It has a compact footprint, saving valuable factory floor space and facilitating integration into existing production layouts.

How to operate and maintain the Disc Top Assembly Machine?

Operating and maintaining a

Disc Top Assembly Machine requires following specific guidelines and procedures to ensure its proper functioning. Here are some general steps for operating and maintaining the machine:

Read the Manual: Familiarize yourself with the manufacturer's manual and instructions specific to the Disc Top Assembly Machine model you have. It will provide detailed guidance on operating procedures, safety precautions, and maintenance requirements.

Set Up the Machine: Prepare the machine for operation by ensuring it is securely placed on a stable surface. Connect the power supply and any necessary peripherals, such as air compressors or conveyor belts, following the manufacturer's instructions.

Pre-Operation Check: Perform a pre-operation check to ensure all components, mechanisms, and safety features are in proper working order. Verify that all necessary materials, such as disc top caps and containers, are readily available.

Load Caps and Containers: Follow the machine's instructions to load the disc top caps and containers into the feeding mechanism or designated areas. Ensure proper alignment and positioning to facilitate smooth assembly.

Regular Inspection: Regularly inspect the machine during operation for any abnormalities, such as loose components, misalignments, or unusual noises. Address these issues promptly to prevent any potential damage or production disruptions.

Cleaning and Sanitization: Regularly clean and sanitize the machine to maintain hygienic conditions, especially if it is used in industries such as food or pharmaceuticals. Use appropriate cleaning agents and methods recommended by the manufacturer.

русский

русский Español

Español عربى

عربى